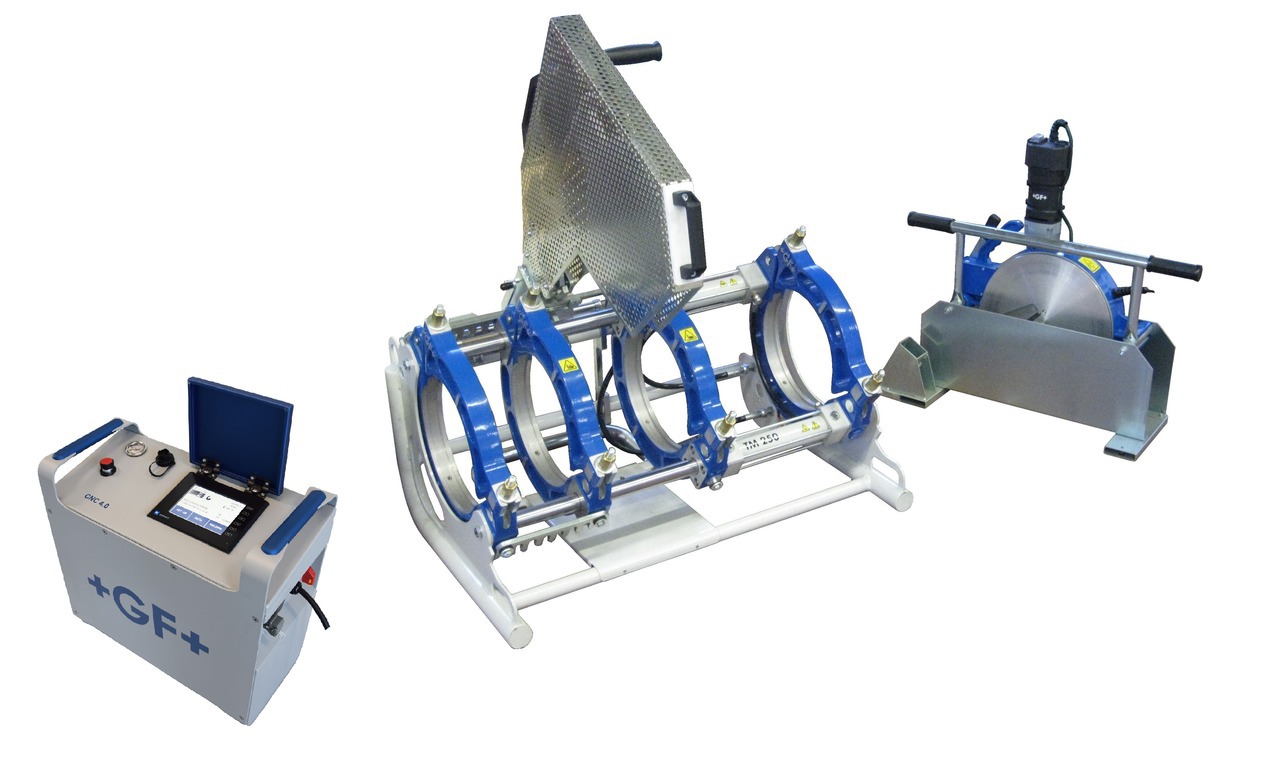

George Fischer CNC 4.0 series, Range 63mm - 315mm

Automatic Butt Fusion Welder

Globally recognized as a market leader in poly pipe butt fusion equipment,

George Fischer CNC 4.0 is manufactured by George Fischer, and is one of the most efficient, Robust and reliable welders in the world. Providing 100% successful joints time after time.

Hydraulic butt fusion machine for heavy-duty operations on construction sites with automatic control unit and touchscreen interface for operator guidance. Bluetooth version available for real time communication from the field.

- Butt Fusion machine to joint PE, PP, PB pipes and fittings for pressure piping systems on building sites and in trenches.

Hydraulically operated with automatic CNC control unit.

Automatic ejection system for the heating element.

- Including transport packaging (wooden crate); reduction clamping inserts and other accessories to be ordered separately.

- BASE MACHINE

High precision design, distortion-free and sturdy machine frame. Good accessibility thanks to 35° inclination. The movable (sliding) 3rd clamp allows easy and time-saving fixation of bends or tees without need of additional tools. Clamps are hinged on the top side and tilting. Whenever necessary, the four clamps can be quickly removed. The heating element is removed automatically during the change-over phase.

The distance control (potentiometer) mounted into the base machine grants control and safety throughout the complete working process.

- Weight: Type 250 = 54 kg, Type 315 = 60 kg

- HYDRAULIC UNIT

- Compact aluminium case with innovative design.

- Intuitive colour touch screen interface.

Operator guidance from preparation to the end of the jointing process by use of symbols and graphics.

Automatic calculation, regulation and control of the fusion parameters - pressure, time and temperature - according to country specific guidelines.

- Real time communication with mobile smartphone during the welding process, the data transfer and fusion protocols collection, in combination with WeldinAir mobile application

- Operator ID (ISO 12176-3), job number and pipe codes (ISO 12176-4) input by means of the smartphone

- Transfer of collected fusion data directly from jobsite to the headquarter by means of the smartphone

- Compatible with label printer

- Integrated GPS receiver

10 freely programmable fusion cycles (e.g. for non standard pipe dimensions)

Selection of language

On site check of the memorized fusion protocols status directly on the touchscreen

Transfer of memorized fusion protocols to an external PC via USB memory stick (included)

Fusion protocols compatible with Welding Book application

Integrated power outlets for planer, heating element Accumulator for pressure equalization during the cooling phase Max operating pressure: 160 bar

Weight: 33 kg

PLANER

Powerful parallel planer for single or double-sided facing of pipe ends Ergonomic, weight-balanced handling Self-locking mechanism in working position

Safety microswitch to prevent undesired start-up - Weight: Type 250 = 14 kg, Type 315 = 17 kg

- HEATING ELEMENT

High performance, electronically controlled heating element High-quality, non-stick PTFE-coating with long service life Temperature indicator integrated into the handle - Weight: Type 250 = 15 kg, Type 315 = 19 kg

- Input power: Type 250 = 2000 W, Type 315 = 2500 W

- CASE

For safe storage of planer and heating element - Weight: Type 250 = 9 kg, Type 315 = 10 kg